Search

Latest topics

» N & C Midwest: Nov. Dec. 2024by OhioGardener Today at 5:06 pm

» Cooked worms?

by KiwiSFGnewbie Today at 4:56 pm

» Tree roots, yeeessss.....

by KiwiSFGnewbie Today at 12:17 am

» New SFG gardener in Auckland

by KiwiSFGnewbie Yesterday at 11:25 pm

» Kiwi's SFG Adventure

by KiwiSFGnewbie 11/12/2024, 7:10 pm

» Thanksgiving Cactus

by OhioGardener 11/12/2024, 5:40 pm

» Happy Birthday!!

by sanderson 11/11/2024, 11:57 am

» Need Garden Layout Feedback

by markqz 11/9/2024, 9:16 pm

» Thai Basil

by Scorpio Rising 11/8/2024, 8:52 pm

» How best to keep a fallow SFG bed

by KiwiSFGnewbie 11/8/2024, 8:11 pm

» Preserving A Bumper Tomato Harvest with Freezing vs Canning

by plantoid 11/7/2024, 11:36 am

» Mark's first SFG

by sanderson 11/6/2024, 11:51 pm

» What Have You Picked From Your Garden Today

by OhioGardener 11/5/2024, 2:29 pm

» Greetings from Southeastern Wisconsin

by sanderson 11/5/2024, 2:01 pm

» Spinning Compost Bin-need some ideas

by rtfm 11/2/2024, 7:49 pm

» Growing fruit trees in Auckland

by OhioGardener 10/31/2024, 4:23 pm

» Vermiculite -- shipping sale through 10/31/2024

by markqz 10/30/2024, 2:27 pm

» N & C Midwest: October 2024

by Scorpio Rising 10/30/2024, 10:38 am

» What are you eating from your garden today?

by Scorpio Rising 10/27/2024, 10:27 pm

» Old Mulch and Closing Beds for Winter

by sanderson 10/26/2024, 11:00 pm

» Ohio Gardener's Greenhouse

by OhioGardener 10/25/2024, 7:17 pm

» Hello from Land of Umpqua, Oregon Zone 8b

by sanderson 10/25/2024, 3:14 pm

» Hello everyone!

by SFGHQSTAFF 10/24/2024, 3:22 pm

» Senior Gardeners

by sanderson 10/23/2024, 6:09 pm

» Hello from South Florida

by markqz 10/23/2024, 10:30 am

» Confirm what this is

by sanderson 10/11/2024, 2:51 pm

» Harlequin Beetles?

by sanderson 10/7/2024, 3:08 pm

» N & C Midwest: September 2024

by OhioGardener 9/30/2024, 4:13 pm

» The SFG Journey-Biowash

by OhioGardener 9/29/2024, 8:33 am

» Fall is For Garlic Planting

by Scorpio Rising 9/28/2024, 12:19 am

Google

Aluminum and Vinyl Table Top

+3

CapeCoddess

AtlantaMarie

MackerelSky

7 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Aluminum and Vinyl Table Top

Aluminum and Vinyl Table Top

Hi All, thought I would share some photos of the weekend table top project.

This is the section of aluminum framing that I decided to use for this first one. It used to hang in a convenience store. As is, it's about 10' long.

This will be it's location and it's sitting East to West end to end. This picture was taken from my front door of the house so it will be easy to access.

Saturday morning I attached two treated 2x4's to the bottom and dug it into the soil to get it as close to level as possible. Had to take about 6" of soil from under the left end. Put down some cardboard and newspaper for grass control and it will later be filled with bark in and around the base

Decided to cut the unsupported ends off of the unit. I lost two foot in length but then I didn't have to figure an end support system. I cut it off leaving a 1/2" past the frame so I didn't have to cut/mess with the welds that are a main part of support for the unit.

Then I glued a 1/2" strip of vinyl to make the box come out even.

I had a few scraps of 1/2" vinyl laying around and figured purchasing one more 4' x 8' sheet would be enough to build it the way I wanted. This picture is with the 'base' of the boxes cut and glued into place. I left some spacing between the three parts for the main base but will probably still drill a few holes before MM.

Then it was time to part putting the sides on. I made them 9 1/2" inches with a table saw and it ends up giving me 7 1/4" deep boxes. I cut them to length and then clamped them in place. I used 2" self tapping screws to anchor them along the bottom and in the corners

I finished up the main box and moved on to that 'rounded' corner of the 'Top Hat'. Attached the first three screws on the right hand side first and then started working my way around the corner using my hip for pressure along with clamping as I went and then putting screws in as I was able to. It went pretty good for 9 1/2" of vinyl.

I added the other two sides of the top hat.

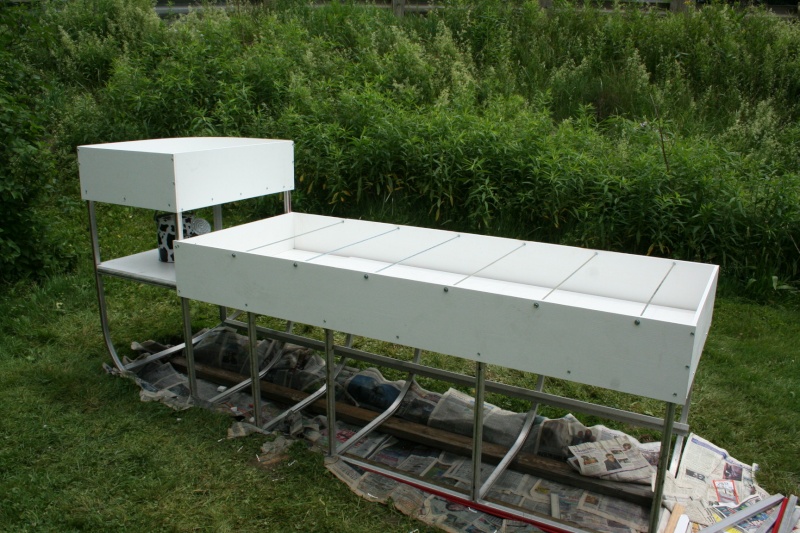

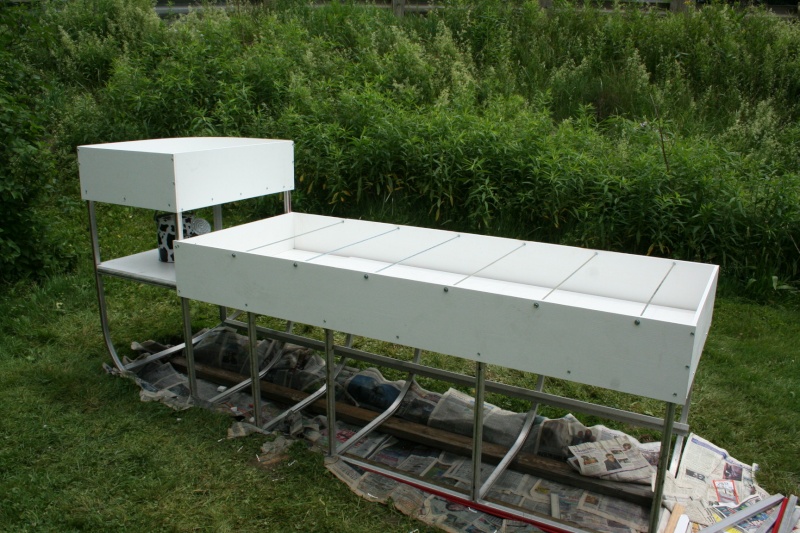

And now the boxes are built and I'm beginning to think this might just work.

This morning after a little rain hit I went out to put the final pieces to the puzzle in. I needed some sort of support for the tops of those long sides of the main box. I figured that the six of so inches of mix would bow the tops out when filled up. So I bought three pieces of 6' one quarter inch 'all thread', cut them to length and put nuts and washers on the inside and outside of the box edges.

This also gives us our 1' markers in that direction.

So this is what we ended up with for inside the box final dimensions. If my math hasn't failed me, the main box is 16.25 sq. ft. and the top hat is a little less than 5 sq. ft. as I loose a little for the corner. 21 or so sq. ft. of space, I'll take it.

From the ground to the top of the main box is 32" while it measures 44" for the top hat. My lady is already using her shelf with the cow watering can...

If the welds all hold this puppy should last us a long time.

All the Best

Brad

This is the section of aluminum framing that I decided to use for this first one. It used to hang in a convenience store. As is, it's about 10' long.

This will be it's location and it's sitting East to West end to end. This picture was taken from my front door of the house so it will be easy to access.

Saturday morning I attached two treated 2x4's to the bottom and dug it into the soil to get it as close to level as possible. Had to take about 6" of soil from under the left end. Put down some cardboard and newspaper for grass control and it will later be filled with bark in and around the base

Decided to cut the unsupported ends off of the unit. I lost two foot in length but then I didn't have to figure an end support system. I cut it off leaving a 1/2" past the frame so I didn't have to cut/mess with the welds that are a main part of support for the unit.

Then I glued a 1/2" strip of vinyl to make the box come out even.

I had a few scraps of 1/2" vinyl laying around and figured purchasing one more 4' x 8' sheet would be enough to build it the way I wanted. This picture is with the 'base' of the boxes cut and glued into place. I left some spacing between the three parts for the main base but will probably still drill a few holes before MM.

Then it was time to part putting the sides on. I made them 9 1/2" inches with a table saw and it ends up giving me 7 1/4" deep boxes. I cut them to length and then clamped them in place. I used 2" self tapping screws to anchor them along the bottom and in the corners

I finished up the main box and moved on to that 'rounded' corner of the 'Top Hat'. Attached the first three screws on the right hand side first and then started working my way around the corner using my hip for pressure along with clamping as I went and then putting screws in as I was able to. It went pretty good for 9 1/2" of vinyl.

I added the other two sides of the top hat.

And now the boxes are built and I'm beginning to think this might just work.

This morning after a little rain hit I went out to put the final pieces to the puzzle in. I needed some sort of support for the tops of those long sides of the main box. I figured that the six of so inches of mix would bow the tops out when filled up. So I bought three pieces of 6' one quarter inch 'all thread', cut them to length and put nuts and washers on the inside and outside of the box edges.

This also gives us our 1' markers in that direction.

So this is what we ended up with for inside the box final dimensions. If my math hasn't failed me, the main box is 16.25 sq. ft. and the top hat is a little less than 5 sq. ft. as I loose a little for the corner. 21 or so sq. ft. of space, I'll take it.

From the ground to the top of the main box is 32" while it measures 44" for the top hat. My lady is already using her shelf with the cow watering can...

If the welds all hold this puppy should last us a long time.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Brad, I am so impressed..... That looks sturdy & should last a GOOD long time.

And no bending over! Woo-hoo...!

You could probly put another shelving unit underneath & have a double-decker for shorter things - radish, beets, basil.

And no bending over! Woo-hoo...!

You could probly put another shelving unit underneath & have a double-decker for shorter things - radish, beets, basil.

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Thanks Marie,

We're going to let it evolve, see how this one works out and how the boss wants to handle it. She's the one that said she didn't want a bed where that shelf is, she will use it for storage, harden off young plants, etc. But the sides could be easily added if that's the way she wants it.

I have four more sections so we'll see how it goes, could be a busy building year.

All the Best

Brad

We're going to let it evolve, see how this one works out and how the boss wants to handle it. She's the one that said she didn't want a bed where that shelf is, she will use it for storage, harden off young plants, etc. But the sides could be easily added if that's the way she wants it.

I have four more sections so we'll see how it goes, could be a busy building year.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

I'm speechless...

Seems to me YOU can build ANYthing! Being as construction-challanged as I am, how you turned that weird looking thing into that neat looking tabletop is beyond me.

Well done!

CC

Seems to me YOU can build ANYthing! Being as construction-challanged as I am, how you turned that weird looking thing into that neat looking tabletop is beyond me.

Well done!

CC

CapeCoddess- Posts : 6811

Join date : 2012-05-20

Age : 68

Location : elbow of the Cape, MA, Zone 6b/7a

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Thanks CC,

Been doing work with the hands all my life, but until it was done I still wasn't sure it would work. Plan your work, work your Plan, right?

Wednesday, I'm going to be working at a weld/machine shop for a guy, putting in a little kitchenette for him and I'm going to take a piece of the aluminum and have him give me a quote for say a 10' x 3' frame, just to see what it would cost. I think non rotting construction would be a benefit for everyone that gardens and maybe I could get a little side business going putting them together for folks.

All the Best

Brad

Been doing work with the hands all my life, but until it was done I still wasn't sure it would work. Plan your work, work your Plan, right?

Wednesday, I'm going to be working at a weld/machine shop for a guy, putting in a little kitchenette for him and I'm going to take a piece of the aluminum and have him give me a quote for say a 10' x 3' frame, just to see what it would cost. I think non rotting construction would be a benefit for everyone that gardens and maybe I could get a little side business going putting them together for folks.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Very cool looking, and I really like that 30-inch width. I find 4x4 boxes cumbersome, and much prefer a 2-foot width ... but think about half a foot wider is even better for the plants that really like to spread. And to help promote air circulation and reduce chances of disease.

Add in the extra height you've got, and it seems to me you've got a just about perfect set-up!

Add in the extra height you've got, and it seems to me you've got a just about perfect set-up!

Marc Iverson-

Posts : 3637

Posts : 3637

Join date : 2013-07-05

Age : 63

Location : SW Oregon

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Although I've never had a 4' elevated bed to work with Marc, I tend to agree they can sometimes be a pain in the hiney for maintenance.

My lady and I had talked about making this frame 3 or 4' wide, using 2x4 as cantilever on either side, but it always came back to making sure the welds were going to hold up under the weight.

Should have it filled by Tuesday evening and then maybe start planning another.

All the Best

Brad

My lady and I had talked about making this frame 3 or 4' wide, using 2x4 as cantilever on either side, but it always came back to making sure the welds were going to hold up under the weight.

Should have it filled by Tuesday evening and then maybe start planning another.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Brad - Your box is a thing of beauty! I look forward to seeing it filled and sprouting. You and your lady will have one awesome looking set-up when you get the rest of them put together!

Goosegirl-

Posts : 3424

Posts : 3424

Join date : 2011-02-16

Age : 59

Location : Zone 4A - NE SD

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Lol, I've never been told I had a beautiful box before GooseGirl!!!Goosegirl wrote:Brad - Your box is a thing of beauty! I look forward to seeing it filled and sprouting. You and your lady will have one awesome looking set-up when you get the rest of them put together!

Taking a little lunch break then work for a few more hours and get the MM home to mix it up. I was told this morning that some flowers are going in first...Grrrrrrr.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

..Lol, I've never been told I had a beautiful box before...

Get used to it!

I think that's the most weather-impervious, maintenance-free TT that I've seen.

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Was able to get MM put together last night and into the boxes. We've had nearly a half an inch of rain overnight and into this morning, so it got a pretty good soaking rain.

Just guesstimating it took about 13cu ft. of mix. I figure approximately 325 to 350lbs of weight from the mix and then add in the weight of the moisture and it seems to be sitting fine

Just guesstimating it took about 13cu ft. of mix. I figure approximately 325 to 350lbs of weight from the mix and then add in the weight of the moisture and it seems to be sitting fine

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Wow! Look at that thing just waiting to be planted. Gives me itchy fingers!

CC

CC

CapeCoddess- Posts : 6811

Join date : 2012-05-20

Age : 68

Location : elbow of the Cape, MA, Zone 6b/7a

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Yeah, the ole lady has been looking thru the seeds on hand and making a list/graph. Then I had to remind her(because I'm like that) to 'fall planting will begin in around 6 weeks'. That Glare!(seen it hundreds of times) So, she gets up and opens a blind to the side yard and two more of those TT frames I had pulled out earlier today were sitting there. She pointed, I nodded, she smiled and I went to the shed to start planning the next bed!CapeCoddess wrote:Wow! Look at that thing just waiting to be planted. Gives me itchy fingers!

CC

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Yeah, that Honey-Do list just keeps gettin' bigger...... Happens around here too.

Canopy Pictures

Canopy Pictures

When I first posted my intentions for this table top, I knew I had pictures of the frame as a canopy hanging in a store- But I couldn't find them. Yesterday when we were receiving 1.10" inches of rain that we didn't need, I found another usb drive that had some photos of the store remodel.

First one is along the outside of the canopy and the aluminum ribs of the frame are visible

This one is from the back side and you can see the aluminum frame through more of a 'see through' cover

And just another look from across the front

My lady stopped by the forum the other day and looked at this post and asked me how are people going to understand what that was without pictures? and she was right. So now I can send her the link with photos and maybe it will clarify for those that couldn't visualize what it used to be. Thanks Pam...(maybe she'll register now)

Since it's so close to the end of the month, I can honestly say that this will be the first June since moving here in 1989 that we've not had to water the gardens. Seems the 5.89" we've gotten came in intervals that made it unnecessary. Hopefully July will bring some sun and some warmer weather.

All the Best

eL Brado

First one is along the outside of the canopy and the aluminum ribs of the frame are visible

This one is from the back side and you can see the aluminum frame through more of a 'see through' cover

And just another look from across the front

My lady stopped by the forum the other day and looked at this post and asked me how are people going to understand what that was without pictures? and she was right. So now I can send her the link with photos and maybe it will clarify for those that couldn't visualize what it used to be. Thanks Pam...(maybe she'll register now)

Since it's so close to the end of the month, I can honestly say that this will be the first June since moving here in 1989 that we've not had to water the gardens. Seems the 5.89" we've gotten came in intervals that made it unnecessary. Hopefully July will bring some sun and some warmer weather.

All the Best

eL Brado

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Thanks for the update.

I had thought your frames were for outdoor awnings that are on the face of storefronts. That they were made of aluminum was puzzling. All the awnings that I have seen were made of thin gauge steel that was galvie, painted, or powder coated.

Now I get it!

I had thought your frames were for outdoor awnings that are on the face of storefronts. That they were made of aluminum was puzzling. All the awnings that I have seen were made of thin gauge steel that was galvie, painted, or powder coated.

Now I get it!

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Thanks for posting the before photos. Have you or you lady planted in the new bed?

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Yeah boffer, that's why I was kind of hesitant about the 'welds' through this process, the frames were not really designed for snow load or even wind stress. Just built to hang there with some vinyl attached to them in a controlled climate. We'll see how it makes out through the rest of the growing season and then a winter here. For now, it seems fine.boffer wrote:

I had thought your frames were for outdoor awnings that are on the face of storefronts. That they were made of aluminum was puzzling. All the awnings that I have seen were made of thin gauge steel that was galvie, painted, or powder coated.

@sanderson Pam's gotten a couple of different radishes in and up, some fennel, lettuce and spinach. A square of each just to see but she'll begin to fill it up with some fall crops in a few weeks. We both have agreed that we can make this our 'salad' box late into the year and first thing in the spring.

When I filled it with MM, I took a trowel and made a 4" x 4" hole in the mix in both the Top Hat and the main box. Stuffed some shredded paper to about 3" deep, put in a scoop of compost that had worms/eggs in it, fed them some scraps and covered both of the holes back over with MM. The middle of last week, I noticed the food was getting low so I went straight across the box's 30" width, made a hole, put in newspaper and food. Yesterday I dug back into the new holes and a few worms had migrated to the new food, hopefully 'pooping' the whole way. I'll give it another week and plant some more food in a different square and see how it goes. Hopefully we'll have plenty of worms working when we plant for fall.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

Thought I would take a little time and update this thread with the way things are growing. Very happy with the table top and the way we just walk out the front door for fresh greens.

The table top with a medley of lettuce, spinach and carrots. Planted a couple seeds of Black and Red Russian Kale in the empty square in front corner this morning. We've never grown it but want to give it a try

Table top from the end = fresh salad 24/7

This is another frame in the approximate location that it will be set up. I'm thinking of expanding it to a full 36" wide this time instead of the 30" as before. This one is a full 10' long so we'll have a full 30 sq. feet.

I'm going to try an experiment with this one. I'll be putting a solid vinyl bottom and try a wicking system. First, I'm going to put a 100' heat tape coiled in the bottom of the box. Then I'm going to place some 2 1/2 strips of vinyl on edge, four or five of them, to form a raised floor and put these pieces below across them to give me the actual base of the growing box. These pieces hopefully will form the 'wicking' for the heated water.

I'll then place a growing fiber on top of the metal, fill the box with approximately 7" MM and see if it works. I'll have two drain plugs on the bottom of the box and two overflow hoses for the water. I'll then be able to drain it if I decide not to run it all winter. Who knows, with a hoop frame, well, we'll see. Hopefully it will at least extend my growing season on each end.

I'll be building it over the next ten days or so and get it planted for fall, so more pics are sure to come.

All the Best

Brad

The table top with a medley of lettuce, spinach and carrots. Planted a couple seeds of Black and Red Russian Kale in the empty square in front corner this morning. We've never grown it but want to give it a try

Table top from the end = fresh salad 24/7

This is another frame in the approximate location that it will be set up. I'm thinking of expanding it to a full 36" wide this time instead of the 30" as before. This one is a full 10' long so we'll have a full 30 sq. feet.

I'm going to try an experiment with this one. I'll be putting a solid vinyl bottom and try a wicking system. First, I'm going to put a 100' heat tape coiled in the bottom of the box. Then I'm going to place some 2 1/2 strips of vinyl on edge, four or five of them, to form a raised floor and put these pieces below across them to give me the actual base of the growing box. These pieces hopefully will form the 'wicking' for the heated water.

I'll then place a growing fiber on top of the metal, fill the box with approximately 7" MM and see if it works. I'll have two drain plugs on the bottom of the box and two overflow hoses for the water. I'll then be able to drain it if I decide not to run it all winter. Who knows, with a hoop frame, well, we'll see. Hopefully it will at least extend my growing season on each end.

I'll be building it over the next ten days or so and get it planted for fall, so more pics are sure to come.

All the Best

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

It's nice to hear that you're enjoying the benefits of a TT near the door. That's almost as fun as designing and building the TT!

I've made a 4x4 SFG TT wicking box, and I have some boxes with soil heating cables in them, but I haven't heard of anyone combining the two. This will be interesting!

A heated box definitely allows me to get started earlier in the spring. Besides getting plants in earlier, I've used them to start my own seedlings by planting 5 broccoli or cauliflower seeds per square, and then transplanting 4 of them. I haven't tried extending the season in the fall with a heated box.

I can recommend lining the box with insulation to create a thermal break; it will make the system more efficient. I've used ½-1 inch foam board, and the ¼ inch bubble wrap sandwiched between foil. I can't tell that one is more effective than the other, but occasionally the foil will peel off the bubble wrap where it is in constant contact with damp MM. It's not a problem-just unsightly.

What I can't figure out from your description, is how the wicking will work. Will the MM be in contact with the water somehow, or will you be using some type of wicking material that is in contact with both the MM and water?

I've made a 4x4 SFG TT wicking box, and I have some boxes with soil heating cables in them, but I haven't heard of anyone combining the two. This will be interesting!

A heated box definitely allows me to get started earlier in the spring. Besides getting plants in earlier, I've used them to start my own seedlings by planting 5 broccoli or cauliflower seeds per square, and then transplanting 4 of them. I haven't tried extending the season in the fall with a heated box.

I can recommend lining the box with insulation to create a thermal break; it will make the system more efficient. I've used ½-1 inch foam board, and the ¼ inch bubble wrap sandwiched between foil. I can't tell that one is more effective than the other, but occasionally the foil will peel off the bubble wrap where it is in constant contact with damp MM. It's not a problem-just unsightly.

What I can't figure out from your description, is how the wicking will work. Will the MM be in contact with the water somehow, or will you be using some type of wicking material that is in contact with both the MM and water?

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

I did leave the 'wicking' part out, age maybe? What I'm thinking of doing boffer is using some of a 300' or so roll of 1/4" nylon rope that's resting in the shop and weave them thru the holes, leaving a couple of inches dangling in the water and hopefully drawing water up to the bottom of the soil. Might it work?boffer wrote:

What I can't figure out from your description, is how the wicking will work. Will the MM be in contact with the water somehow, or will you be using some type of wicking material that is in contact with both the MM and water?

I do plan on putting a 1" foam board on top of the frame as I build it, then put the floor on and if I want to add insulation to the outside of the walls of the box, I can to that later.

Basically, it's just a little experiment trying to combine the best of two worlds and I 'ain't afraid to fail'. I appreciate any input...

Brad

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

My first thought is that the nylon rope is not going to wick very well. I put some ¼ inch nylon rope in 2½ inches of water with food coloring added. No wicking seen in the first 15 minutes. I'll let it sit for a day or two.

You mentioned that you'll be using heat tape. Is that the product used to wrap water pipes to protect from freezing?

I've used 'soil heating cables'. Basically, it's the same stuff as I've put under floor tile, only it comes with a built-in, waterproof thermostat, with a non-adjustable on-off temp of around 73°. External thermostats are an available option.

Are you thinking about putting the thermostat (or temp probe) in the MM or in the water?

I like the idea of a heated wicking box, but I'm still mulling over the possible advantages/disadvantages of heating the water, rather than the MM itself.

You mentioned that you'll be using heat tape. Is that the product used to wrap water pipes to protect from freezing?

I've used 'soil heating cables'. Basically, it's the same stuff as I've put under floor tile, only it comes with a built-in, waterproof thermostat, with a non-adjustable on-off temp of around 73°. External thermostats are an available option.

Are you thinking about putting the thermostat (or temp probe) in the MM or in the water?

I like the idea of a heated wicking box, but I'm still mulling over the possible advantages/disadvantages of heating the water, rather than the MM itself.

Re: Aluminum and Vinyl Table Top

Re: Aluminum and Vinyl Table Top

You might want to drill a few thicker holes and stuff them with more rope. There is a lot of great discussion on tomatoville.com about wicking and the properties of different wicking materials that makes a great read. One of things I found and that seemed confirmed by some of the discussion and instructionals I've read is that if you use modest wicking, you get modest water uptake.

I built wicking containers that had a single central wick, and even though it was thicker than recommended, I still didn't get enough water moving up through it to make the system effective. Only when I greatly increased the width and number of wicks in my next container -- the only one I'm still using today -- did I get plants to thrive in it without relying nearly entirely on top-down watering.

I built wicking containers that had a single central wick, and even though it was thicker than recommended, I still didn't get enough water moving up through it to make the system effective. Only when I greatly increased the width and number of wicks in my next container -- the only one I'm still using today -- did I get plants to thrive in it without relying nearly entirely on top-down watering.

Marc Iverson-

Posts : 3637

Posts : 3637

Join date : 2013-07-05

Age : 63

Location : SW Oregon

Page 1 of 2 • 1, 2

Similar topics

Similar topics» Longevity of boxes

» Vinyl Grid

» What to do with hot vinyl fence??

» Can I use vinyl siding?

» rasied garden bordering question?

» Vinyl Grid

» What to do with hot vinyl fence??

» Can I use vinyl siding?

» rasied garden bordering question?

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum