Search

Latest topics

» Coduri Temu [acr639380] Reducere De 100 Lei La Prima Comandaby shaw410 Today at 2:16 am

» Temu Popust Kod [acr639380] Ostvarite 40% Popusta Hrvatska

by shaw410 Today at 2:15 am

» Temu Cod Reducere Romania [acr639380] Până La 100€ Reducere

by shaw410 Today at 2:14 am

» Temu Coupon Code $100 Off [acu729640] First Order

by Aruz64 Today at 1:58 am

» Temu Rabattkod Sweden [acu729640] 40% Rabatt För Ny Användare

by Aruz64 Today at 1:57 am

» Codigo Desconto Temu [acu729640] 100€ Desconto Primeira Compra

by Aruz64 Today at 1:54 am

» New SFG gardener in Auckland

by sanderson Today at 12:14 am

» Mark's first SFG

by sanderson Yesterday at 11:51 pm

» How best to keep a fallow SFG bed

by KiwiSFGnewbie Yesterday at 3:03 am

» Need Garden Layout Feedback

by sanderson 11/5/2024, 2:33 pm

» What Have You Picked From Your Garden Today

by OhioGardener 11/5/2024, 2:29 pm

» Greetings from Southeastern Wisconsin

by sanderson 11/5/2024, 2:01 pm

» N & C Midwest: Nov. Dec. 2024

by Scorpio Rising 11/3/2024, 3:51 pm

» Spinning Compost Bin-need some ideas

by rtfm 11/2/2024, 7:49 pm

» Kiwi's SFG Adventure

by KiwiSFGnewbie 10/31/2024, 9:55 pm

» Growing fruit trees in Auckland

by OhioGardener 10/31/2024, 4:23 pm

» Vermiculite -- shipping sale through 10/31/2024

by markqz 10/30/2024, 2:27 pm

» N & C Midwest: October 2024

by Scorpio Rising 10/30/2024, 10:38 am

» What are you eating from your garden today?

by Scorpio Rising 10/27/2024, 10:27 pm

» Old Mulch and Closing Beds for Winter

by sanderson 10/26/2024, 11:00 pm

» Ohio Gardener's Greenhouse

by OhioGardener 10/25/2024, 7:17 pm

» Hello from Land of Umpqua, Oregon Zone 8b

by sanderson 10/25/2024, 3:14 pm

» Hello everyone!

by SFGHQSTAFF 10/24/2024, 3:22 pm

» Senior Gardeners

by sanderson 10/23/2024, 6:09 pm

» Hello from South Florida

by markqz 10/23/2024, 10:30 am

» Happy Birthday!!

by sanderson 10/18/2024, 3:09 am

» Confirm what this is

by sanderson 10/11/2024, 2:51 pm

» Harlequin Beetles?

by sanderson 10/7/2024, 3:08 pm

» Preserving A Bumper Tomato Harvest with Freezing vs Canning

by sanderson 10/7/2024, 3:05 pm

» N & C Midwest: September 2024

by OhioGardener 9/30/2024, 4:13 pm

Google

Best rain barrel instructions

+15

sanderson

PNG_Grandma

boffer

plantoid

Unmutual

Pepper

llama momma

westie

Goosegirl

camprn

Sunsanvil

mrwes40

stripesmom

Rob C

claudiamedic

19 posters

Page 1 of 2

Page 1 of 2 • 1, 2

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Only have a couple pics here but will do it justice in about a week when I get back home and can take some for a tutorial lesson in my way of doing it, not that its the only or best but works well for me.

The first pic is a dry run of assembly ,barrels are upside down from final so I can measure and cut each piece for a nice fit. The second pic kinda shows the spigot on the left but shows the extra T for a clean out in the fall, a plug that has a compression screw rod fits in it. Last pic is the final installation of each barrel onto the manifold. Once in place a hole is carefully cut in the top of the end barrel for the inlet. I replaced the downspout with plastic corrugated 3” farm tile and put a double layer of screen cloth in the hole first for a junk filter. The filter gets punched down for room for the junk to collect and not restrict flow. I clean the filter usually after each rain for good housekeeping. All parts came from my small town farm store, any decent hardware or box store should have a one stop offering. Will take more pics later this is a trial at posting pics, Thanks camprn for the help. Need to add that some holes in the tops of the barrels are necessary to let out air pressure, I used 1/8” drill bit and made 4 holes in a small box group about 1/2” apart. Did not cover them but if a bug walking in bothers you then cement a piece of screen over the holes.

The first pic is a dry run of assembly ,barrels are upside down from final so I can measure and cut each piece for a nice fit. The second pic kinda shows the spigot on the left but shows the extra T for a clean out in the fall, a plug that has a compression screw rod fits in it. Last pic is the final installation of each barrel onto the manifold. Once in place a hole is carefully cut in the top of the end barrel for the inlet. I replaced the downspout with plastic corrugated 3” farm tile and put a double layer of screen cloth in the hole first for a junk filter. The filter gets punched down for room for the junk to collect and not restrict flow. I clean the filter usually after each rain for good housekeeping. All parts came from my small town farm store, any decent hardware or box store should have a one stop offering. Will take more pics later this is a trial at posting pics, Thanks camprn for the help. Need to add that some holes in the tops of the barrels are necessary to let out air pressure, I used 1/8” drill bit and made 4 holes in a small box group about 1/2” apart. Did not cover them but if a bug walking in bothers you then cement a piece of screen over the holes.

westie- Posts : 48

Join date : 2012-03-27

Location : Iowa

Re: Best rain barrel instructions

Re: Best rain barrel instructions

When rain fills all the barrels, where does the continuing flow of water go?? All over the lawn? Or do you have to run outside to turn some kind of diverter so it flows back to the downspout?

llama momma

Certified SFG Instructor-

Posts : 4914

Posts : 4914

Join date : 2010-08-20

Location : Central Ohio zone 6a

Re: Best rain barrel instructions

Re: Best rain barrel instructions

This is definitely not a project for this year, but I may be able to set up something like this next spring. That should be enough time to collect everything I need and then plan out a day for assembly!

GG

GG

Goosegirl-

Posts : 3424

Posts : 3424

Join date : 2011-02-16

Age : 59

Location : Zone 4A - NE SD

Re: Best rain barrel instructions

Re: Best rain barrel instructions

The overflow now goes to a second set of barrels from a 2” overflow near the top of this set and the inlet on them is about the same. The overflow from the second set is also a pipe near the top on the side and goes to the regular runoff just like before there were any barrels there. When I get back home next week I will give proper detail in a follow up post with more pics so you can see my entire setup with step by step explanation.

westie- Posts : 48

Join date : 2012-03-27

Location : Iowa

Re: Best rain barrel instructions

Re: Best rain barrel instructions

GG the youtube video showed an overflow arangement between the barrels. There would have to be some opening at/or near the new top to allow air to escape else there will be a pressure lock, preventing proper filling/draining. Or as westie said drill small holes to alow air to flow.....

Pepper-

Posts : 563

Posts : 563

Join date : 2012-03-04

Location : Columbus, Ga

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Sunsanvil wrote:Are there ever any concerns about runoff from whatever the roof is made off being in the water and getting into our gardens? I have to imagine that ceramic tile roofs are more benign than, say, asphalt.

Might seem silly, but just askin'. We're trying to be as "organic" as possible.

Find out what asphalt shingles were used on your roof. Some are made with biocides, some contain heavy metals, some may be perfectly safe if you use a first flush system.

If your shingles have some type of fungicide(and moldicide) in the runoff, these can be an issue in the garden, especially the fungicides, since it can kill mycorrhizae and any other beneficial fungi(like the fungus used in nitrogen fixing). There are some beneficial molds, like slime molds(I think they like to break down partially decomposed woody items more than anything else).

I believe metal roofs are the best "normal" roofs for harvesting rainwater. Though I don't see why ceramic tiles would be bad, unless for roofing they also have the some form of biocide.

Though I do have to admit that I'm not sure of the impact from using contaminated rainwater from an asphalt roof and how watered down(sorry for the pun) any biocide would be if any leached out. If there's anything that I hate about doing gardening research is the lack of detailed information about so many things and the dogmatic way people say "Don't use that!" and don't explain why in good enough detail...kind of like what I'm doing now.

http://ag.arizona.edu/region9wq/pdf/Palau_catchmentmanual.pdf says to avoid using water from asphalt shingles, but that's for drinking water(page 6).

Unmutual

Certified SFG Instructor-

Posts : 391

Posts : 391

Join date : 2011-04-23

Age : 52

Location : Greater New Orleans Area Westbank(Zone 9b)

Re: Best rain barrel instructions

Re: Best rain barrel instructions

ROB! Those are awesome! Thanks for the great pictures. I'm forwarding all this info to my girl-Friday who will hopefully feel up to a project soon. I'm watching it pour down rain right now and wishing I had those barrels (sitting on my patio, closed) set up! It is supposed to be very dry here this summer....

Keep the suggestions and PICTURES coming!

Keep the suggestions and PICTURES coming!

Re: Best rain barrel instructions

Re: Best rain barrel instructions

"Rob - the connection of PVC on the bottom - is that the only connection

between the barrels for water to flow from one to the other, or do you

have connections at the top as well? Just wondering if it is set up to

fill one, then overflow to the other or to fill all three from the

bottom at the same time with the one visible overflow on the front

barrel when all are full.

Inquiring minds want to know!

GG - who has free access to as many of these blue barrels as she wants..."

GG-

The 3/4" PVC is the only connection between the barrels and all three fill from the bottom to the same level. I forgot to mention that in this setup, you need to drill a small hole in the top of each barrel to allow the air to escape as they fill.

westie- Great looking system. The strange threads on the one bung are called Buttress threads. I had considered using 2" PVC but 3/4 was less expensive so I thought I'd see if it works. So far they seem to fill and drain ok.

Thanks everyone for the compliments.

between the barrels for water to flow from one to the other, or do you

have connections at the top as well? Just wondering if it is set up to

fill one, then overflow to the other or to fill all three from the

bottom at the same time with the one visible overflow on the front

barrel when all are full.

Inquiring minds want to know!

GG - who has free access to as many of these blue barrels as she wants..."

GG-

The 3/4" PVC is the only connection between the barrels and all three fill from the bottom to the same level. I forgot to mention that in this setup, you need to drill a small hole in the top of each barrel to allow the air to escape as they fill.

westie- Great looking system. The strange threads on the one bung are called Buttress threads. I had considered using 2" PVC but 3/4 was less expensive so I thought I'd see if it works. So far they seem to fill and drain ok.

Thanks everyone for the compliments.

Rob C-

Posts : 33

Posts : 33

Join date : 2012-04-19

Age : 63

Location : Horsham, PA

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Unmutual wrote:Sunsanvil wrote:Are there ever any concerns about runoff from whatever the roof is made off being in the water and getting into our gardens? I have to imagine that ceramic tile roofs are more benign than, say, asphalt.

Might seem silly, but just askin'. We're trying to be as "organic" as possible.

Find out what asphalt shingles were used on your roof. Some are made with biocides, some contain heavy metals, some may be perfectly safe if you use a first flush system.

If your shingles have some type of fungicide(and moldicide) in the runoff, these can be an issue in the garden, especially the fungicides, since it can kill mycorrhizae and any other beneficial fungi(like the fungus used in nitrogen fixing). There are some beneficial molds, like slime molds(I think they like to break down partially decomposed woody items more than anything else).

I believe metal roofs are the best "normal" roofs for harvesting rainwater. Though I don't see why ceramic tiles would be bad, unless for roofing they also have the some form of biocide.

Though I do have to admit that I'm not sure of the impact from using contaminated rainwater from an asphalt roof and how watered down(sorry for the pun) any biocide would be if any leached out. If there's anything that I hate about doing gardening research is the lack of detailed information about so many things and the dogmatic way people say "Don't use that!" and don't explain why in good enough detail...kind of like what I'm doing now.

http://ag.arizona.edu/region9wq/pdf/Palau_catchmentmanual.pdf says to avoid using water from asphalt shingles, but that's for drinking water(page 6).

I've been using rain water on the veg collected from Ash Felt , galv zinc , plastic or asbestos sheet covered shed roofs for donkeys years . usually stored in a steel 45 gallon drum or a 600 litre plastic food grade barrel .

I suppose someone thinks the tar & oils in the Ash Felt is harmful , as kids we had our hair washed in the soft rain water collected in this manner .. Ok so I'm 61 and almost bald but that's down to male verility .

The pollution alone in the air that comes down with the rain will most likely as damaging , especially if you live close to aircraft flight lines or freeways / motorways or other traffic busy roads..

plantoid-

Posts : 4093

Posts : 4093

Join date : 2011-11-09

Age : 73

Location : At the west end of M4 in the UK

Re: Best rain barrel instructions

Re: Best rain barrel instructions

There are diverters available, retail, that will allow a pre-determined amount of rain to 'clean' the roof of pollen, pollution, dirt, bird droppings, etc. before the rain is diverted into the barrels. For instance, you could set the diverter to allow 0.5 inches of the first rain downfall to be carried away as usual, then to divert to collect the continuing rain in your barrels.

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Thanks for posting all this great information. Until very recently this isn't a subject I even thought about... but should have! A few weeks ago I read something about rain harvesting and began doing a bit of research. Al thought I was crazy and just laughed at me, until he watched some YouTube videos and read a few articles, then he said he was all in. Yay... true to my nature I didn't waste any time beginning a new project! Here's what we did, and why ... a bit lengthy with the photos and descriptions, but I hope it might help someone else.

Rain Harvesting Project, February 2014, Central Valley of CA

Due to the severe drought in California at this time, and the long-range forecasts for more of the same, we have decided to be proactive and build a Rain Harvesting system in our yard.

Our goal is to continue to water our backyard garden boxes and keep some if not all our flowering landscape alive, without using the City water.

The following pictures and descriptions will detail our progress, and the frustrations we've faced building our system. While YouTube videos are helpful they are not entirely descriptive!

The first step was to find the correct type of barrels to use. There are many types of rain-barrels available at all the big box stores with prices ranging from around $50 to well over $200 for a small system. The YouTube videos recommended using only food grade barrels or those containing soap. An extensive search on CraigsList provided many ads with many more prices. An ad for a local dealer connected us to a really great guy who delivered six 55 gallon blue food grade barrels to us. He advertised the barrels at $12 each but in the phone conversation he said it was an old ad and they were now $15. Not entirely pleased, but interested in him delivering the barrels for just $5 in gas money, I agreed to purchase the six barrels. We gave him $100 for his efforts, $5 more than he requested. The following day I contacted him again and we agreed to him delivering 8 more barrels for $12.50 each since the old ad was still running. He had only one blue barrel and 7 white barrels, which were not my preference since white barrels are reported to grow algae in the sunlight. He delivered the eight additional barrels and we now had 14 barrels... 7 blue and 7 white.

With the space limitations in our yard we chose to build two horizontal systems. Each system will be four barrels on the bottom row and three more stacked on top, all on their sides. One system will be on the east side of our house near the back of our awning at the downspout, and the other will be on the west side, again at the backside of the awning near the downspout. The white barrel system will be in the shady area on the east side, the blue barrels will be in full sun on the west side. Each system will harvest the rainwater from the entire roof and awnings of our home.

We began with the white barrels and the system on the shady east side of the house.

The area where the system will be built is a rocky ground cover so we purchased 24 - 8” x 8” x 16” concrete blocks for two rows, 12 blocks each, separated by 3-4” which provides a base 35” by approximately 48”.

Al began by placing the blocks on the rocky base, leveling as he made the two rows for the base.

The following day he completed the base.

To prevent the barrels from rolling Al made “cradles” for the barrels. These cradles will also support the weight of the water along the sides of the barrels... front, middle, and rear. These cradle strips were treated with a wood preservative to prevent rotting from the elements.

After watching many videos on the construction of these systems we decided to use 2” PVC pipe and fittings. Many other systems were built with 3/4” pipes and fittings but the builders later said the inflow of rainwater was much too fast for the 3/4” size to handle. Our 2” piping and fittings may be a bit large but we want to harvest every bit of rainwater available without overflowing.

While at The Home Depot searching for fittings we realized that the “bungs” in the lids of each barrel have two different threads. One bung (the screw in caps on the lids of the barrels) has a regular pipe thread and the other has a very coarse thread. For the regular thread we used a 2” fitting. A short piece of pipe was then cut to attach the “tee” fitting to the screwed in cap fitting. This will allow the barrels to be connected together for the water to flow into each barrel. Here are the first four barrels lined up on the cradles with the first fittings in place.

With a fresh outlook and more determination we began again on our project. Even though it seemed a total waste of time and effort we “dry fitted” all the parts, most all of the parts.

The frustrations of trying to level every section EACH and EVERY time we moved even one small part … well, there were many moments of total silence, and a few with not so much silence!

Once we found the parts were fitting the way they should, as long as we straightened the barrels and leveled them vertically and horizontally … we began taking it all apart. Seems like a waste, but this is how we had to do it. Fit it all together, then take it all apart. The 2” pieces all fit. Because they do we took a chance that the 3/4” pieces would fit as well.

The 3/4” pipes and fittings were for the air venting. To allow the barrels to fill properly we must have vents for the air to escape. Remember when I described the two different bungs in the lids of these barrels? One had a regular pipe thread and the other had a much coarser thread. This coarse threaded bung is left in the barrel and just the center is drilled out. There is a 3/4” threaded area in the center of these bungs and when drilled out the remaining threads are a perfect fit for a 3/4” fitting. The challenge here is trying to get the centers drilled out without moving the darned barrels! Any pushing or pulling immediately misaligned the barrels both side to side and up and down. Grrrr.

Time for some deep breathing... we're about to jump off into the unknown... we're gonna use the glue!

This glue lets us have about 15 seconds to decide if we've got it right or not. If not...too bad, it's done. Yikes!

We took a little break, just sat down and talked about exactly how we'd go about putting the pieces together. Our first thought was to just start at one end and then move from barrel to barrel. Hmmm, not so fast! By starting with the center two barrels we would have the flexibility of moving each outside barrel just a wee bit to get the fittings in place before that glue dried. Not only were we gluing the fittings in place but we also had to level the fittings AND get the barrels into place … all in less than 15 seconds!!!

Lots of tight-lipped silence happening. Probably better than #%@&!!!, right???

Once the glue was set, and we took another short break to breathe again... we knew we had to seal every part that might possibly leak. We had purchased a couple of tubes of Gutter Adhesive, made for exactly this... well, almost exactly this application. The clear sealant pushed into all the little nooks and crannies and threaded areas of the fittings. This stuff stayed pliable while we moved it around and smooshed it into the areas most likely to leak.

Hey, we're almost finished!! The air vent is in place, we just have to connect to a downspout... somehow.

Because we live in a mobile home, or manufactured home... the fittings, parts, pieces, just about every single thing is a tiny bit different than a regular house. The downspout fittings are no exception. Not one single downspout had the same end piece as on our gutters. Not in stores, not online. We had to again get a bit creative … we bought a regular downspout accordion fit extender downspout with larger rectangular end pieces. Our gutter has a smallish square piece that attaches to the squarish downspout built for our house. The end of the new downspout was just gonna have to fit inside the hard rubber but somewhat flexible 3” to 2” fitting we bought. The 2” part had no problems fitting over our 2” PVC pipe and was clamped on with the built in screw-type clamp. One end working just fine. Well, with a bit of adjusting. I brought out my hair dryer, heated the end of the downspout and we stuffed the rectangular end inside the round fitting. HA, it worked! Clamped it down before it could change it's mind about cooperating, and one more part finished!

Al punched a small hole in the sidewall of the upper section of the downspout and put a large hook through it... hanging it from the gutter much the way we hang our plants. This is a temporary fix, doesn't look very pretty but it works!

We hope we're finished with this first rain harvesting system. We've watched a bunch of videos on YouTube with guys telling us all sorts of things … some very technical and other just plain outlandish! Not one video had a detailed guide along with a suggested shopping list. We stopped a couple of videos and printed still images to take to The Home Depot with us to find parts. Mostly we improvised and created our own system as we went along. We should harvest about 345 gallons of rainwater … hope our hard work pays off!

Please let us know what you think of our rain harvesting system.

Rain Harvesting Project, February 2014, Central Valley of CA

Due to the severe drought in California at this time, and the long-range forecasts for more of the same, we have decided to be proactive and build a Rain Harvesting system in our yard.

Our goal is to continue to water our backyard garden boxes and keep some if not all our flowering landscape alive, without using the City water.

The following pictures and descriptions will detail our progress, and the frustrations we've faced building our system. While YouTube videos are helpful they are not entirely descriptive!

The first step was to find the correct type of barrels to use. There are many types of rain-barrels available at all the big box stores with prices ranging from around $50 to well over $200 for a small system. The YouTube videos recommended using only food grade barrels or those containing soap. An extensive search on CraigsList provided many ads with many more prices. An ad for a local dealer connected us to a really great guy who delivered six 55 gallon blue food grade barrels to us. He advertised the barrels at $12 each but in the phone conversation he said it was an old ad and they were now $15. Not entirely pleased, but interested in him delivering the barrels for just $5 in gas money, I agreed to purchase the six barrels. We gave him $100 for his efforts, $5 more than he requested. The following day I contacted him again and we agreed to him delivering 8 more barrels for $12.50 each since the old ad was still running. He had only one blue barrel and 7 white barrels, which were not my preference since white barrels are reported to grow algae in the sunlight. He delivered the eight additional barrels and we now had 14 barrels... 7 blue and 7 white.

With the space limitations in our yard we chose to build two horizontal systems. Each system will be four barrels on the bottom row and three more stacked on top, all on their sides. One system will be on the east side of our house near the back of our awning at the downspout, and the other will be on the west side, again at the backside of the awning near the downspout. The white barrel system will be in the shady area on the east side, the blue barrels will be in full sun on the west side. Each system will harvest the rainwater from the entire roof and awnings of our home.

We began with the white barrels and the system on the shady east side of the house.

The area where the system will be built is a rocky ground cover so we purchased 24 - 8” x 8” x 16” concrete blocks for two rows, 12 blocks each, separated by 3-4” which provides a base 35” by approximately 48”.

Al began by placing the blocks on the rocky base, leveling as he made the two rows for the base.

The following day he completed the base.

To prevent the barrels from rolling Al made “cradles” for the barrels. These cradles will also support the weight of the water along the sides of the barrels... front, middle, and rear. These cradle strips were treated with a wood preservative to prevent rotting from the elements.

After watching many videos on the construction of these systems we decided to use 2” PVC pipe and fittings. Many other systems were built with 3/4” pipes and fittings but the builders later said the inflow of rainwater was much too fast for the 3/4” size to handle. Our 2” piping and fittings may be a bit large but we want to harvest every bit of rainwater available without overflowing.

While at The Home Depot searching for fittings we realized that the “bungs” in the lids of each barrel have two different threads. One bung (the screw in caps on the lids of the barrels) has a regular pipe thread and the other has a very coarse thread. For the regular thread we used a 2” fitting. A short piece of pipe was then cut to attach the “tee” fitting to the screwed in cap fitting. This will allow the barrels to be connected together for the water to flow into each barrel. Here are the first four barrels lined up on the cradles with the first fittings in place.

With a fresh outlook and more determination we began again on our project. Even though it seemed a total waste of time and effort we “dry fitted” all the parts, most all of the parts.

The frustrations of trying to level every section EACH and EVERY time we moved even one small part … well, there were many moments of total silence, and a few with not so much silence!

Once we found the parts were fitting the way they should, as long as we straightened the barrels and leveled them vertically and horizontally … we began taking it all apart. Seems like a waste, but this is how we had to do it. Fit it all together, then take it all apart. The 2” pieces all fit. Because they do we took a chance that the 3/4” pieces would fit as well.

The 3/4” pipes and fittings were for the air venting. To allow the barrels to fill properly we must have vents for the air to escape. Remember when I described the two different bungs in the lids of these barrels? One had a regular pipe thread and the other had a much coarser thread. This coarse threaded bung is left in the barrel and just the center is drilled out. There is a 3/4” threaded area in the center of these bungs and when drilled out the remaining threads are a perfect fit for a 3/4” fitting. The challenge here is trying to get the centers drilled out without moving the darned barrels! Any pushing or pulling immediately misaligned the barrels both side to side and up and down. Grrrr.

Time for some deep breathing... we're about to jump off into the unknown... we're gonna use the glue!

This glue lets us have about 15 seconds to decide if we've got it right or not. If not...too bad, it's done. Yikes!

We took a little break, just sat down and talked about exactly how we'd go about putting the pieces together. Our first thought was to just start at one end and then move from barrel to barrel. Hmmm, not so fast! By starting with the center two barrels we would have the flexibility of moving each outside barrel just a wee bit to get the fittings in place before that glue dried. Not only were we gluing the fittings in place but we also had to level the fittings AND get the barrels into place … all in less than 15 seconds!!!

Lots of tight-lipped silence happening. Probably better than #%@&!!!, right???

Once the glue was set, and we took another short break to breathe again... we knew we had to seal every part that might possibly leak. We had purchased a couple of tubes of Gutter Adhesive, made for exactly this... well, almost exactly this application. The clear sealant pushed into all the little nooks and crannies and threaded areas of the fittings. This stuff stayed pliable while we moved it around and smooshed it into the areas most likely to leak.

Hey, we're almost finished!! The air vent is in place, we just have to connect to a downspout... somehow.

Because we live in a mobile home, or manufactured home... the fittings, parts, pieces, just about every single thing is a tiny bit different than a regular house. The downspout fittings are no exception. Not one single downspout had the same end piece as on our gutters. Not in stores, not online. We had to again get a bit creative … we bought a regular downspout accordion fit extender downspout with larger rectangular end pieces. Our gutter has a smallish square piece that attaches to the squarish downspout built for our house. The end of the new downspout was just gonna have to fit inside the hard rubber but somewhat flexible 3” to 2” fitting we bought. The 2” part had no problems fitting over our 2” PVC pipe and was clamped on with the built in screw-type clamp. One end working just fine. Well, with a bit of adjusting. I brought out my hair dryer, heated the end of the downspout and we stuffed the rectangular end inside the round fitting. HA, it worked! Clamped it down before it could change it's mind about cooperating, and one more part finished!

Al punched a small hole in the sidewall of the upper section of the downspout and put a large hook through it... hanging it from the gutter much the way we hang our plants. This is a temporary fix, doesn't look very pretty but it works!

We hope we're finished with this first rain harvesting system. We've watched a bunch of videos on YouTube with guys telling us all sorts of things … some very technical and other just plain outlandish! Not one video had a detailed guide along with a suggested shopping list. We stopped a couple of videos and printed still images to take to The Home Depot with us to find parts. Mostly we improvised and created our own system as we went along. We should harvest about 345 gallons of rainwater … hope our hard work pays off!

Please let us know what you think of our rain harvesting system.

PNG_Grandma-

Posts : 297

Posts : 297

Join date : 2010-06-20

Age : 76

Location : Modesto CA, Central Valley, USDA Zone 9b, Sunset 14, AHS Heat Zone 8, whew!

... more about our rain harvesting system

... more about our rain harvesting system

I was asked about the stability of our barrels... what keeps the bottom barrels from rolling apart when the top barrels fill. Great question! These barrels will weigh about 400 pounds when filled with water... they won't fill to capacity due to the location of the fill holes and vent holes, but still, they WILL be pretty darned heavy!

In the detailed instructions posted on the other topic pages we showed the 2x4 strips we placed at the base of each outside barrel, just for this purpose. Before the barrels fill with too much water we will either put two thick rods of rebar (taller than the top barrels) into the ground at each end of the system and link the tops of the rebar together with chain ... or we'll place tie-down straps around the entire system to hold them in place.

None of the videos on YouTube speak of any barrels rolling apart, but if these were to break free when full of water they would take out that post on the left that holds up the awning on our house that's attached to our roof. DISASTER!! Not to mention the potential harm to any humans standing nearby. Yes, we've thought of the safety issues too.

Here in the Central Valley in CA we occasionally have a small earthquake, nothing large... and because we're mostly on sand we have a low rolling quake, not the harsh jolts of the more coastal areas of CA. We think we've prepared for just about any problems...

With that said, I must tell you that after the rain began today, and enough came down to fill the gutter a bit and drip into the downspout ... we found a problem. We forgot to glue the last few fittings!! The downspout was clamped to the black flexible fitting that you see in the picture and it was clamped to the 45° fitting that was attached to the 2" pipe which went into a "T" fitting then continued on down to the 90° fitting to begin filling the bottom barrels. We forgot to glue the 45° and the Tee fittings!! They were leaking... but hey, that was exciting to see because it meant the system was working!!! During a lull in the light rain Al quickly glued the fittings and wiped off the outside drips. Over an hour later and there are no new drips... and it's still raining. YAY!! Seems like it's working. Again, whew.

In the detailed instructions posted on the other topic pages we showed the 2x4 strips we placed at the base of each outside barrel, just for this purpose. Before the barrels fill with too much water we will either put two thick rods of rebar (taller than the top barrels) into the ground at each end of the system and link the tops of the rebar together with chain ... or we'll place tie-down straps around the entire system to hold them in place.

None of the videos on YouTube speak of any barrels rolling apart, but if these were to break free when full of water they would take out that post on the left that holds up the awning on our house that's attached to our roof. DISASTER!! Not to mention the potential harm to any humans standing nearby. Yes, we've thought of the safety issues too.

Here in the Central Valley in CA we occasionally have a small earthquake, nothing large... and because we're mostly on sand we have a low rolling quake, not the harsh jolts of the more coastal areas of CA. We think we've prepared for just about any problems...

With that said, I must tell you that after the rain began today, and enough came down to fill the gutter a bit and drip into the downspout ... we found a problem. We forgot to glue the last few fittings!! The downspout was clamped to the black flexible fitting that you see in the picture and it was clamped to the 45° fitting that was attached to the 2" pipe which went into a "T" fitting then continued on down to the 90° fitting to begin filling the bottom barrels. We forgot to glue the 45° and the Tee fittings!! They were leaking... but hey, that was exciting to see because it meant the system was working!!! During a lull in the light rain Al quickly glued the fittings and wiped off the outside drips. Over an hour later and there are no new drips... and it's still raining. YAY!! Seems like it's working. Again, whew.

PNG_Grandma-

Posts : 297

Posts : 297

Join date : 2010-06-20

Age : 76

Location : Modesto CA, Central Valley, USDA Zone 9b, Sunset 14, AHS Heat Zone 8, whew!

Re: Best rain barrel instructions

Re: Best rain barrel instructions

PNG_Grandma and others, Any updates on your rain water collection systems? For desert and dry dwellers, these can be food for thought.

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Thanks for asking! We built a second set of rain barrels for the west side of our house but weren't sure how much would actually fill. We can't see the water in these blue barrels but only guess by the sound when we tap them. The image is not tilted, the barrels are! Our driveway slopes from our backyard to the street and we didn't think we'd have a problem ... so far, no problem. During the rain we had on Oct 31 and Nov 1st, not a long rain, but enough to fill the barrels and shoot the water back out the air vent! By the time I grabbed the camera the shooting up water had lessened, but you can still see it pouring out of the 3/4" upright PVC air vent pipe.

During the summer Al used water from our white barrels to do some of our plants in the yard and the backyard container gardens. With the rain on Nov 1st the white barrels filled again. It is mind boggling to see how fast these barrels fill, and with only 1/4 of our roof, possibly just from the awnings on both sides of our mobile home. Our home is 24 x53 but the awnings add another 12' to each side... so our rain collecting roof area is 48' x 53' ... and the barrels fill from only 1/4 of that area on each side of the house. In the image you can see the water pouring off our neighbors gutter. My personal opinion is that EVERYONE in CA should be collecting at least some of the rainwater ... it's free!

During the summer Al used water from our white barrels to do some of our plants in the yard and the backyard container gardens. With the rain on Nov 1st the white barrels filled again. It is mind boggling to see how fast these barrels fill, and with only 1/4 of our roof, possibly just from the awnings on both sides of our mobile home. Our home is 24 x53 but the awnings add another 12' to each side... so our rain collecting roof area is 48' x 53' ... and the barrels fill from only 1/4 of that area on each side of the house. In the image you can see the water pouring off our neighbors gutter. My personal opinion is that EVERYONE in CA should be collecting at least some of the rainwater ... it's free!

PNG_Grandma-

Posts : 297

Posts : 297

Join date : 2010-06-20

Age : 76

Location : Modesto CA, Central Valley, USDA Zone 9b, Sunset 14, AHS Heat Zone 8, whew!

Rain barrel

Rain barrel

This looks to be pretty simple but it's only a single barrel. I'm going to try this one today.claudiamedic wrote:It seems overwhelming....without any "Mr. Fixit" (or Ms. Fixit) around it is the blind-leading-the-blind. Keep the suggestions coming!

https://www.youtube.com/watch?v=MYTNciCplmw&nohtml5=False

MrBooker-

Posts : 732

Posts : 732

Join date : 2016-03-19

Age : 78

Location : 62260

Re: Best rain barrel instructions

Re: Best rain barrel instructions

I liked the video, looks simple and I already have two barrels in a greenhouse that I no longer use. One for the back and one in the front.

johnp-

Posts : 636

Posts : 636

Join date : 2013-01-05

Age : 79

Location : high desert, Penrose CO

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Our two sets of barrels (7 + 7) are still full and with each brief storm we replenish any water we've used in our yard or the Apollo Garden. During the next few days we might get a small amount of rain here in the Modesto area (we're in the northern part of the central valley of CA) and because the barrels are all full the rain will just run off the roof onto the ground. Always seems so sad that we can't harvest more of that precious water! We're still in "Extreme Drought Conditions" through a good part of CA. The plus side of our 4 yr drought and now having rain - the wild flowers along the freeways and on the hills and out in the desert areas are beyond beautiful! The hills are a gorgeous green with large areas of golden poppies, yellow mustard, the blue and lavenders of the many wildflowers - huge swipes of color seemingly painted with an invisible and ginormous paintbrush!

PNG_Grandma-

Posts : 297

Posts : 297

Join date : 2010-06-20

Age : 76

Location : Modesto CA, Central Valley, USDA Zone 9b, Sunset 14, AHS Heat Zone 8, whew!

Re: Best rain barrel instructions

Re: Best rain barrel instructions

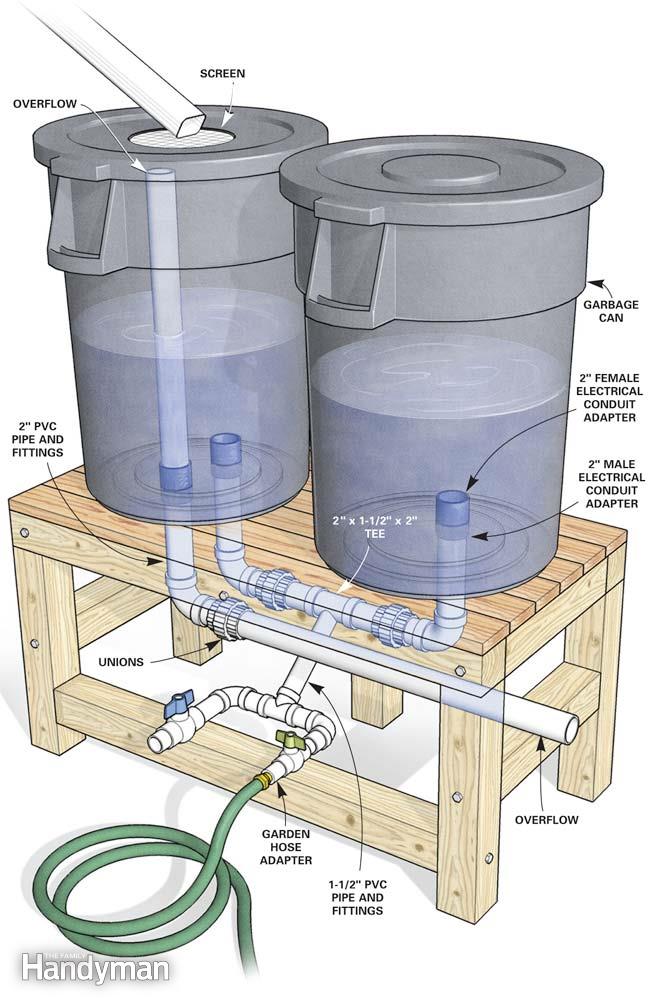

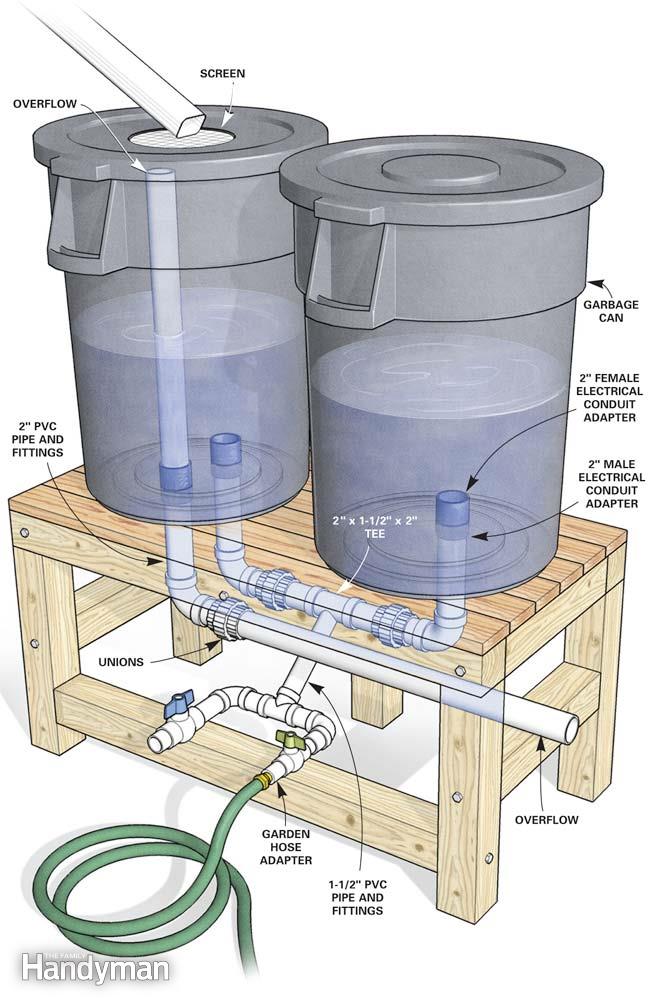

Saw this on Family Handyman:

How to Build a Rain Barrel

How to Build a Rain Barrel

ralitaco-

Posts : 1303

Posts : 1303

Join date : 2010-04-04

Location : Southport , NC

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Bump.

Winter is usually the rainy season, and I'm wondering who actually made a collection system since this thread first started in 2012. New members, do any of you have a system you would like to share?

Winter is usually the rainy season, and I'm wondering who actually made a collection system since this thread first started in 2012. New members, do any of you have a system you would like to share?

Re: Best rain barrel instructions

Re: Best rain barrel instructions

I just put out barrels when it rains. Since the rainy season lasts only four months, that makes it easy to hide them away from the front of the house or use for other tasks (like collecting material for compost).

But it does mean I have to do more work to move the water to where it is needed. I use an old hose, start a siphon on it, and move the water to where it is needed which is fortunately mostly downhill from the house.

But it does mean I have to do more work to move the water to where it is needed. I use an old hose, start a siphon on it, and move the water to where it is needed which is fortunately mostly downhill from the house.

markqz

Forum Moderator- Posts : 968

Join date : 2019-09-02

Location : Lower left hand corner

sanderson likes this post

Re: Best rain barrel instructions

Re: Best rain barrel instructions

Are they 55-gallon containers? It looks like we may get some rain.

https://www.ventusky.com/

https://www.ventusky.com/

Re: Best rain barrel instructions

Re: Best rain barrel instructions

sanderson wrote:Are they 55-gallon containers? It looks like we may get some rain.

https://www.ventusky.com/

Standard 35 gallons.

markqz

Forum Moderator- Posts : 968

Join date : 2019-09-02

Location : Lower left hand corner

sanderson likes this post

Page 1 of 2 • 1, 2

Similar topics

Similar topics» When is it safe to start filling my rain barrel?

» How do you have your rain barrel set up?

» Rain Barrel

» Rain barrel question

» is this a good rain barrel?

» How do you have your rain barrel set up?

» Rain Barrel

» Rain barrel question

» is this a good rain barrel?

Page 1 of 2

Permissions in this forum:

You cannot reply to topics in this forum